Products Description

The dual flange liquid level transmitter is connected to the measured container through two upper and lower flanges. The upper flange and lower flange respectively sense the pressure on the high-pressure side and low-pressure side. When the liquid level in the container changes, there is a difference in pressure between the two ends. The differential pressure is converted into an electrical signal by a sensor, processed by the signal processing unit inside the transmitter, and output a standardized signal (such as 4-20mA) to reflect the liquid level height.

characteristic:

High precision and stability: High precision sensors and advanced signal processing technology ensure the accuracy and stability of liquid level measurement.

Corrosion resistance: Various materials such as stainless steel, Hastelloy, tantalum, etc. can be used for flanges and diaphragms to meet the corrosion requirements of different media.

Adapt to high temperature and high pressure environments: able to work stably in harsh environments such as high temperature and high pressure.

Easy to install and maintain: The double flange design simplifies the difficulty of on-site installation and maintenance.

Output format: Supports 4-20mA output signals, making it easy to integrate into various industrial control systems.

Technical parameter

Install PFA side-mounted flange level transmitter

Extended insertion flange level transmitter

New-Input type liquid level transmitter

Double Flange Level Transmitter

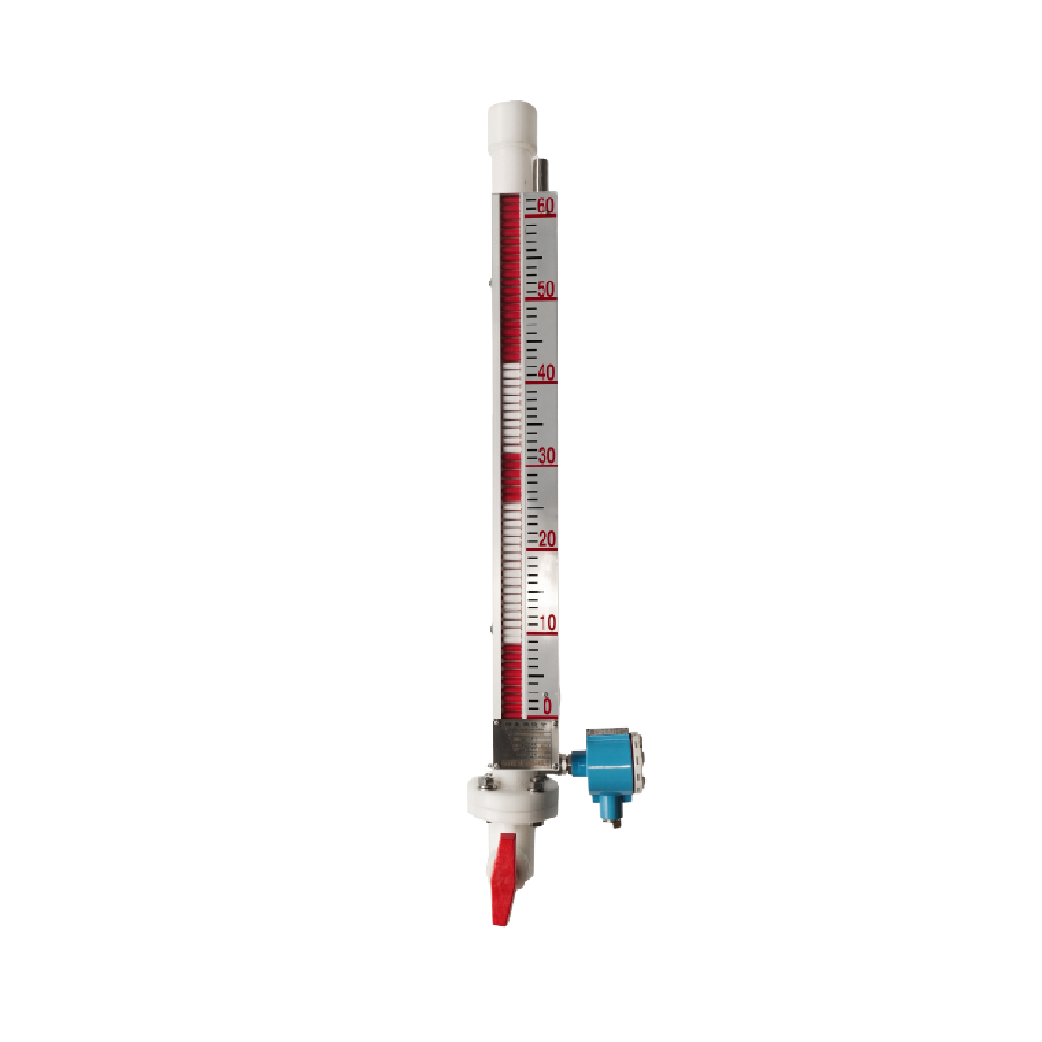

Magnetic flap level indicator

| Instrument model | YGQ7961D/7119 |

| Instrument category | Liquid level transmitter |

| Process Connection | Flanges, threads, and sanitary types |

| 2-inch/DN50/50A | |

| 3-inch/DN80/80A | |

| Range | Range selectable within 0-15m |

| Liquid receiving material | 316L stainless steel |

| Hastelloy C-276 | |

| TA tantalum, NI nickel, T titanium, etc | |

| Accuracy | ±0.1%FS |

| Filling fluid | Low temperature oil XLT |

| DC200 DC704 DC705 | |

| Fluorine oil |